AUSTRALIA

Hot Rolled Products

New Zealand and Pacific

Steel Products

Australia Hot Rolled Products covers the operations of Port Kembla Steelworks, which manufactures steel slab, hot rolled coil and plate. New Zealand and Pacific Steel Products is a fully integrated operation with its own raw materials resource. President Noel Cornish discusses a very strong year.

Q. What was the highlight of 2006/07?

A. While Port Kembla Steelworks and New Zealand Steel both had an extremely good year financially, we are most proud of our safety performance. These businesses achieved a Lost Time Injury Frequency Rate (LTIFR) of 0.23, for both employees and contractors. This is an excellent performance. Further, Port Kembla Steelworks - a very large, complex facility - achieved an LTIFR of zero. These results are due to a tremendous amount of work by our people in Australia and New Zealand.

Operator cleaning the coke ovens bench at Port Kembla Steelworks.

Q. What other achievements were notable during the year?

A. Another highlight for 2006/07 was the reliable supply of products and services to our customers. At both Port Kembla Steelworks and New Zealand Steel, demand was strong for all our products.

We met this demand through increased production volumes and solid delivery performance.

Underpinning this success was a strong financial result. Port Kembla Steelworks achieved revenue of $3.9 billion, an increase of 13 per cent on the previous year. Higher domestic and international prices and outstanding operational performance resulted in an EBIT increase of 66 per cent to $759 million. Production records were set for ironmaking, steelmaking, hot rolled coil and plate. Our New Zealand Steel and Pacific Islands businesses also had good year, with revenue increasing by three per cent to $728 million. The business set records in metallic coated and painted production and showed a 24% pre-tax return on net assets.

Higher zinc costs, a strong New Zealand dollar and capacity constraints led to a 14 per cent decrease in EBIT, to $90 million. Slab production was much stronger toward the end of 2006/07, so we're looking forward to improved throughput in the coming year.

It is worth mentioning that many of these results are records on records. These operations were already demonstrating excellent performance, so to have improved on this is a real achievement.

Q. Given strong operational performance in previous years, how have we managed to achieve even higher production levels?

A. It comes down to one factor - people. Our employees are educated, well trained, motivated and committed and they constitute an extremely stable workforce.

SURELINE® steel power poles, developed in conjuction with the electricity industry, are light weight and long-lasting, as those shown here in Mt Gambier, South Australia.

Q. What challenges did these businesses face in 2006/07?

A. One challenge was preparing for the reline of No. 5 blast furnace at Port Kembla. This work will be undertaken in 2009 and is a $330 million project that must be executed precisely and safely. The fact that we've still achieved a record in ironmaking indicates how well our people have managed to keep this furnace stable and reliable, despite its age.

New Zealand Steel has done a lot of work to optimise slabmaking capacity during the year and we are starting to see the benefits of these efforts.

Q. Could you tell us about other significant projects underway?

A. We are conducting a feasibility study on a major electricity co-generation project at Port Kembla. This project involves generating electricity from gases produced during steelmaking and has the potential to save over 800,000 tonnes of greenhouse gases being released each year. This is equivalent to taking 185,000 cars off the road every year.

Again at Port Kembla, we are ready to upgrade our sinter plant capacity. Increasing iron ore prices have been a major cost impost and this $134 million project will help by enabling the plant to use lower-cost iron ore fines, rather than pellets.

We've also invested in some standout environmental projects.

Our water recycling initiative at Port Kembla Steelworks, in conjunction with Sydney Water, celebrated the use of its three billionth litre of recycled water in May. In the past 10 years, the Port Kembla operation has halved its fresh water consumption, which is having a major positive effect on local water supplies. Ninety-eight per cent of the water we use in steelmaking is now either salt or recycled water.

During the year we also signed a new five-year pollution reduction program. Recent work, such as improvements to our sinter plant to capture and treat gas and dust emissions, has drawn a positive community response.

At New Zealand Steel we are studying a number of projects to further add value by extracting additional minerals from our ironsands deposits.

Q. What does the coming year hold for these businesses?

A. We expect demand for our products to remain strong. The drop in coking coal prices in 2006/07 was positive, however raw material prices for the coming year appear to be increasing.

Q. How would you sum up the 2006/07 financial year?

A. It has been a remarkable year during which all our businesses performed well. We have a highly skilled, talented and motivated team and I thank everyone for contributing to another outstanding result.

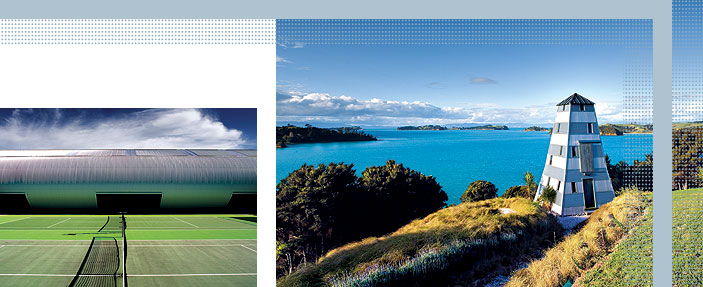

Below: The flexibility of steel is used to dramatic effect in the Tennis Centre at Hamilton, New Zealand. Right: The lighthouse at Waiheke Island, New Zealand, showcases the durability and design scope of ZINCALUME® steel.